Fueling a Cleaner Tomorrow

Sustainability

Meeting Societal Challenges and Market Needs

Unlike other technologies that rely on one primary source of feedstock, the Jupeng Bio process can produce ethanol from numerous feedstocks, including municipal solid waste, yard, forestry, and agricultural waste, while breaking the link between food crops and ethanol production. Because of the flexibility of Jupeng Bio's innovative technology, we can build facilities anywhere in the world, wherever there is waste, providing jobs and locally sourced renewable energy for urban and rural communities.

Leading economics – The outstanding energy efficiency, selectivity to ethanol and feedstock flexibility of the Jupeng Bio advanced bioethanol process result in highly cost-competitive production of ethanol.

Feedstock flexibility - Unlike conventional bioethanol technologies, which use food crops, or the emerging cellulosic fermentation technologies, which can convert cellulose and hemi-cellulose but not lignin, the Jupeng Bio process can convert all ligno-cellulosic materials as well as other carbon materials into ethanol. The range of organic materials that can be used includes, but is not limited to:

- The biogenic portion of municipal solid waste (MSW), which includes garden and food wastes

- Organic commercial & industrial wastes

- Wood waste

- Forestry residues and products (e.g. brash, bark, saw dust, wood chippings)

- Agricultural residues (e.g. sugar cane bagasse, corn stover, straw)

- Ligno-cellulose energy crops (e.g. trees, coppice, miscanthus and switch grass)

Energy efficient - Jupeng Bio's innovative technology delivers high energy efficiency throughout the winning combination of a thermo-chemical process (gasification) and a low temperature, low pressure biochemical process (bacterial fermentation) with excellent heat integration.

Biocatalyst advantages – Conventional catalysts used for the conversion of syngas to transport fuels are expensive to prepare, are easily poisoned, need to be replaced regularly, require high temperatures and pressures, and can have relatively poor selectivity to the target fuel product (e.g. ethanol or diesel). In contrast, the Jupeng Bio biocatalyst is low cost, regenerates itself, is tolerant to impurities in the syngas, has extremely high selectivity to ethanol and operates at low temperature and pressure.

Security of energy supply – The feedstock flexibility of the Jupeng Bio technology enables almost every country in the world to manufacture a portion of its own road transportation fuel from the biomass and wastes it generates. Wherever there are people, wastes are generated and transportation fuels are needed. Every major city in the world could potentially have its own Jupeng Bio plant or plants.

Climate friendly – When the bioethanol is used as a road transport fuel, the greenhouse gas (GHG) emissions are reduced up to 90% compared to gasoline. This outstanding GHG performance puts Jupeng Bio's ethanol at a clear advantage versus bioethanol made from sugar and starch crops and from emerging cellulosic fermentation technologies.

Society – Jupeng Bio's advanced technology meets the key needs of society with a localized approach that reduces wastes going to landfill and air pollution, creates jobs, generates tax revenue and safely produces renewable fuel and clean energy.

Reduced pressure on land use - Significant greenhouse gas (GHG) emission savings can be achieved from the road transport sector without increasing pressure on land use or agrichemical use (e.g. fertilizers and pesticides). The diversion of organic wastes from landfill avoids harmful effects of landfill.

Sustainability - An independent life cycle assessment carried out by Eunomia on the production of Jupeng Bio Ethanol from waste biomass indicates that greenhouse gas savings of more than 90% vs. gasoline could be achieved. A key driver for the increased use of biofuels is to reduce the Green house gas (GHG) emissions from the road transport sector without competing with food, or contributing to land use change.

World changing technology – The Jupeng Bio process has the potential to make a substantial contribution across many policy issues whilst creating significant value to society.

In summary, we believe that the Jupeng Bio process is one of the most sustainable bioethanol production process in the world today.

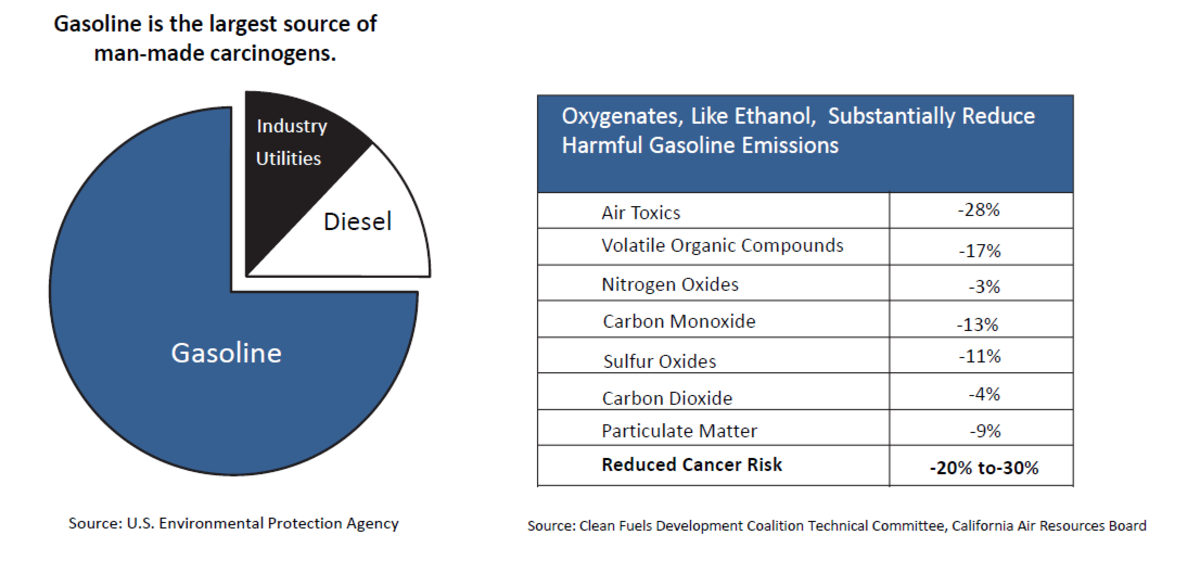

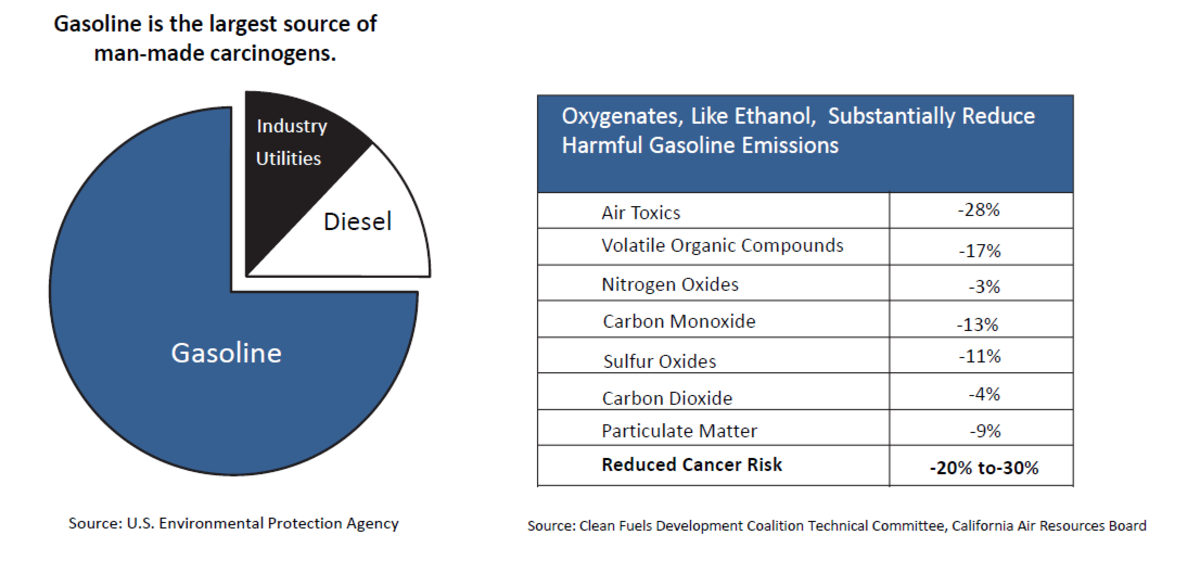

ETHANOL BLENDED INTO GASOLINE SUBSTANTIALLY REDUCES HARMFUL EXHAUST EMISSIONS

© Copyright 2017 by Jupeng Bio Inc.