Fueling a Cleaner Tomorrow

Process Technology

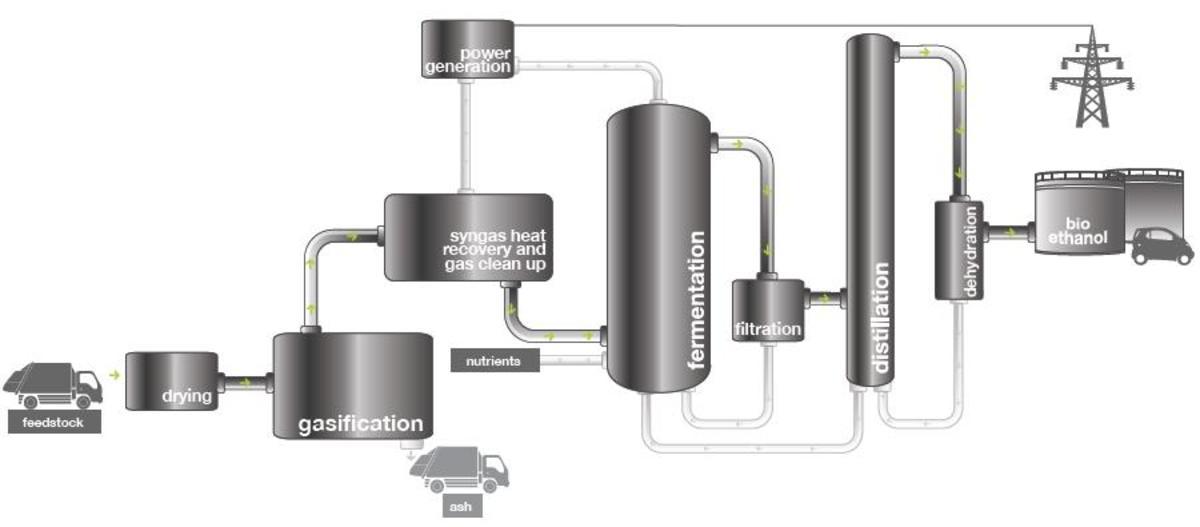

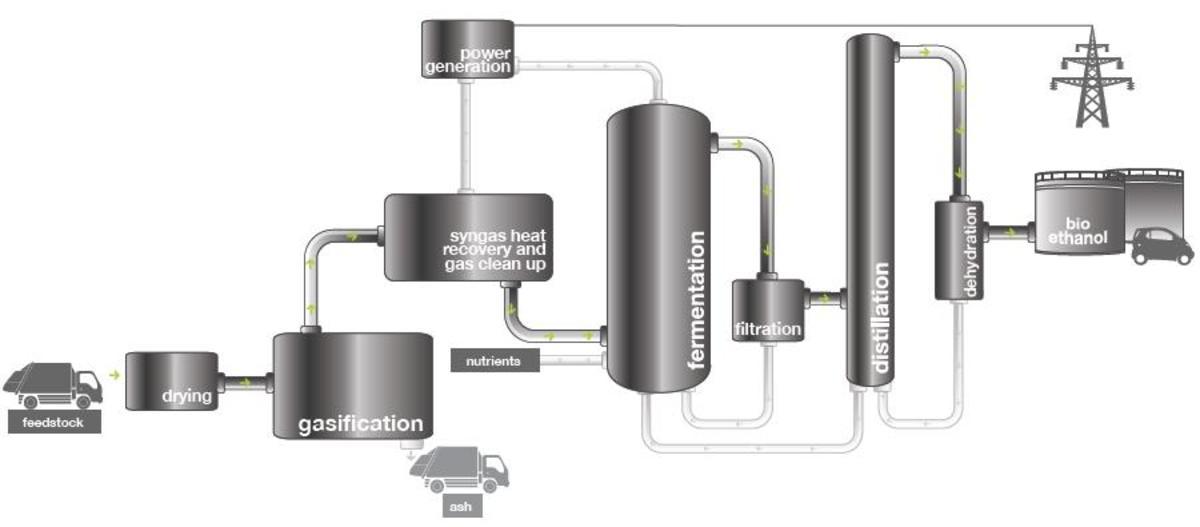

Our Process

1 Feed Handling

The Jupeng Bio process is feed flexible. Before being fed into the gasifier, Organic materials are economically dried through using low grade heat from the process. The process is fully compatible with high recycling rates.

2 Gasification

Organic material is gasified with oxygen at high temperature under controlled conditions to produce synthesis gas, (aka syngas), which is a mixture of principally carbon monoxide (CO) and hydrogen(H2) and carbon dioxide(CO2) gases. Syngas contains important chemical energy and is the building block for the production of bioethanol.

3 Energy Recovery

The hot syngas is cooled and cleaned before being introduced to the fermenter. The heat recovered from the hot syngas is used to generate power for use in the process.

4 Fermentation

The cool, clean syngas is introduced to our fermentation reactor. Our patented bacteria, which are suspended in water, convert the syngas selectively to ethanol. The bacteria biocatalyst is far more effective than all known conventional pathways for syngas conversion to fuels.

5 Bacteria

Our naturally-occurring bacteria are at the heart of our process. The bacteria are found in nature where they have evolved to effectively convert carbon monoxide and hydrogen gases to ethanol. They are maintained in a steady state with the help of small amounts of essential nutrients to achieve a high yield of ethanol.

6 Ethanol PurificationMost of the water is removed from the ethanol solution to produce hydrous ethanol, which is around 96% ethanol in 4% water. The water is returned to the fermenter.

© Copyright 2017 by Jupeng Bio Inc.